Gwajin birki

A cikin bin ka'idodin OCIMF, yana da mahimmanci don gudanar da gwajin ƙarfin birki akan winch na Mooring kafin bayarwa, kowace shekara, da bin duk wani gyare-gyare ko mahimman abubuwan da zasu iya shafar ƙarfin birki. Dangane da sakamakon waɗannan gwaje-gwajen, za a daidaita birki mai kyau don cimma ƙarfin birki na 60% zuwa 80% na mafi ƙarancin fashewar kaya (MBL) na kebul na mooring. Wannan daidaitawa yana tabbatar da cewa idan ƙarfin waje ya zarce ƙarfin birki da aka keɓance, gunkin Mooring zai saki ta atomatik, ta haka zai hana duk wani yuwuwar karyewa ko lahani ga winch ɗin Mooring.

Bidiyon ƙa'idar gwajin ƙarfin birki:

Gwajin Ƙarfin Birki da Gyara

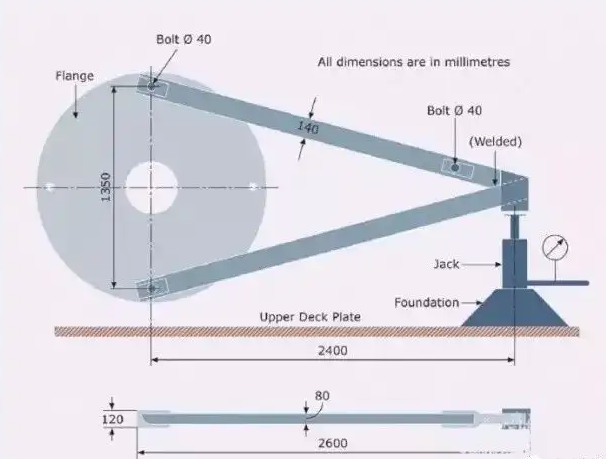

Fara da bitar takaddun shaida na kebul da sauran bayanan da suka dace, tare da ma'aunin filin, don tattara mahimman bayanan dusar ƙanƙara don ƙididdigewa. Jack da mooring winch, sanye take da ma'aunin matsi, dole ne su haɗa da buɗewa don tabbatar da busasshen jack ko yin amfani da ƙuƙumma.

Tsarin lissafin shine kamar haka: T = FxLI/L2 (Kn).

A cikin wannan dabarar, T tana wakiltar ƙarfin jack ɗin da aka ƙididdige (a cikin Kn), wanda yakamata a ƙayyade bisa mafi ƙarancin ƙarfin kebul ɗin jirgin. Wannan lissafin zai samar da karatun ƙarfin jack wanda yayi daidai da ƙarfin birki da ake buƙata, wanda shine ko dai 60% ko 80% na ƙarfin karya na USB. F yana nuna ƙarfin birki na winch ɗin motsi (a cikin Kn). Ll ita ce nisa daga tsakiyar abin nadi mai motsi zuwa tsakiyar kebul, wanda aka lissafta azaman jimlar radius na ciki da radius na USB. L2 yana nuna nisa a kwance daga tsakiyar madaidaicin jack zuwa tsakiyar axis.

Tsarin Gwaji:

1. Yi aiki da ƙugiya don kawar da duk wani danshi, maiko, ko wasu abubuwa waɗanda zasu iya ɓata aikin faifan birki.

2. Haɗa na'urar gwajin daidai gwargwado zuwa madaidaicin winch, tabbatar da an danne birki zuwa daidaitattun matakan, da kuma kawar da kama na winch.

3. Yi amfani da jack don matsa lamba, kuma saka idanu akan karatun ma'aunin matsa lamba a lokacin da birki ya fara zamewa, yin rikodin ƙimar da aka gani.

4. Idan karatun ya faɗi ƙasa da ƙayyadaddun ƙima, wannan yana nuna ƙarancin ƙarfin birki, yana buƙatar ƙara ko gyara birki, sannan a sake gwadawa.

5. Idan karatun ya yi daidai da ƙimar ƙididdiga, yana tabbatar da cewa ƙarfin birki ya cika ka'idojin da aka kafa.

6. Idan madaidaicin winch ɗin bai zamewa ba yayin da karatun jack ɗin ya wuce ƙimar ƙididdigewa, wannan yana nuna cewa birki yana da ƙarfi sosai, yana haifar da ƙarfin birki da yawa. A wannan yanayin, yakamata a rage ƙarfin birki ta hanyar daidaita magudanar birki, sannan a sake gwadawa.

Yawancin jiragen ruwa suna yin gyare-gyaren ƙarfin birki na nasu, yawanci ta hanyar gyaggyara madaidaicin dunƙule a hannun birki don daidaita matsewar birki don mafi kyawun ƙarfi.

Don birki rike da rashin iyakoki, za a iya gano wuri bayan an danne birkin (daidai da karfin birkin da ake so) sannan a yi masa alama duka rikewar birki da band din birki a wancan lokacin (samar da alamar iyaka akan dunƙule birki). A cikin ayyuka na gaba, daidaita alamomi na sama da na ƙasa zai nuna cewa ƙarfin birki a wannan matakin yayi daidai da saita ƙarfin birki.

Bayan kammala gwajin birki, ranar gwajin da ma'aunin ƙarfin birki ya kamata a nuna su sosai a kan ma'aunin motsi kuma a rubuta da kyau a cikin log ɗin kula da kayan aiki.

Matakan Tsaro na Motsawa

Baya ga gwadawa akai-akai da daidaita ƙarfin birki, dole ne kuma a ba da hankali ga abubuwa masu zuwa yayin ayyukan motsa jiki:

Ƙarƙashin Ƙarfafawa:Ƙirƙirar igiyoyin igiyoyi masu motsi suna taka muhimmiyar rawa wajen rarraba jimillar ƙarfin da jirgin ke yi a tsakanin layukan da ke kwance. Misali, idan igiyoyi masu motsi biyu masu girman girman iri daya da kayan sun kasance a tsare zuwa tashar jirgin ruwa a hanya guda amma sun bambanta tsawon - daya yana ninki biyu gwargwadon sauran - guntun kebul ɗin zai jure kashi biyu cikin uku na kaya, yayin da kebul mai tsayi zai ɗauki kashi ɗaya bisa uku kawai. Saboda haka, yana da kyau a yi amfani da igiyoyi masu motsi daidai da tsayi a duk lokacin da zai yiwu.

A cikin lokuta inda igiyoyi biyu na mooring suna da tsayi iri ɗaya, suna da ƙarfi iri ɗaya, kuma suna daidaitawa a hanya ɗaya amma an yi su daga abubuwa daban-daban - irin su kebul na waya na karfe tare da elongation na 1.5% da igiyar fiber na roba tare da elongation na 30% - rarraba kaya zai zama rashin daidaituwa sosai. Kebul ɗin ƙarfe na ƙarfe zai ɗauki kashi 95% na kaya, yayin da igiyar fiber za ta goyi bayan 5%. Don haka, yana da mahimmanci a yi amfani da igiyoyi na kayan abu ɗaya don layukan ɗorawa a hanya ɗaya.

Yana da mahimmanci a gane cewa tabbatar da amincin jirgin ruwa a lokacin hawan (mooring mai tsaro) ya ƙunshi ba kawai daidaituwa da daidaito ba amma har ma da cikakkiyar fahimtar kayan aiki na jirgin ruwa, fahimtar ƙa'idodin motsi, da tsarawa da kuma aiwatarwa. Tsarin kula da matsayi na jirgin a tashar yana farawa ne kawai bayan an tabbatar da jirgin ruwa, wanda ke nuna farkon ci gaba da ayyukan jiragen ruwa.

Mooring Winch Braking Force:Ƙarfin birki na winch mai motsi ya bambanta ga kowane jirgin ruwa kuma ana yin aikin injiniya bisa ga ƙarfin "sakewar kebul" da ke kan kebul ɗin. Wannan ƙarfin yana tasiri da adadin yadudduka na kebul da jagorar iska. Yawan yadudduka na kebul akan drum yana tasiri da ƙarfin birki na tsarin motsi. Don injunan motsi waɗanda basu da ganguna na rabuwa, ƙarfin birki yawanci ana daidaita shi don takamaiman adadin yadudduka. Saboda haka, yana da mahimmanci a tabbatar da cewa igiyoyin sun yi rauni sosai a kan ganga ba tare da sun taru a gefe ɗaya ba, saboda hakan na iya rage ƙarfin birki. A cikin yanayin winches na USB sanye take da ganguna na rabuwa, yana da mahimmanci a kiyaye ba fiye da ɗaya Layer na USB akan ganga mai ƙarfi don hana raguwar ƙarfin birki ba.

Daidaitaccen iska na kebul yana da mahimmanci, saboda rashin dacewa na iya haifar da raguwar ƙarfin birki da kashi 50%.

Rashin Amfani da Birki Mai Kyau:Ma'aikatan jirgin sukan yi kuskuren yin amfani da birki don sassauta kebul ɗin lokacin da yake cikin tashin hankali, wanda hanya ce da ba ta dace ba. Wannan al'ada na iya haifar da rashin daidaituwa a kan bel ɗin birki kuma yana haifar da haɗari na aminci saboda yanayin rashin kulawa. Idan ma'aunin nauyi ya hau ba zato ba tsammani a kan kebul ɗin da ba a kwance ba, zai iya ɗauka, yana haifar da haɗarin haɗari. Hanyar da ta dace ta haɗa da shigar da kama da yin amfani da wuta don kwance kebul ɗin a hankali.

Fasahar Jawo Kebul na Nylon:Lokacin kiyaye kebul na nailan zuwa tari, guji dogaro kawai da kullin “∞” don ƙarawa. Maimakon haka, yi jujjuya biyu (tare da wasu suna ba da shawarar juzu'i ɗaya, amma bai wuce biyu ba) don fara cire kebul ɗin a gefen jirgin, sannan ƙirƙirar kullin “∞” (don manyan ƙulli) ko kuma kunsa tari biyu sau ɗaya kafin ƙirƙirar kullin “∞” (don ƙananan ƙulli). Wannan dabarar tana ba da damar ingantaccen sarrafa kebul kuma yana haɓaka aminci.

Yanki Mai Hatsari Yayin Tsagewar Kebul:Mafi haɗari na igiyoyin fiber na roba yana faruwa lokacin da kebul ya karye kuma ya sake komawa ba zato ba tsammani. Lokacin da igiyar igiya mai matsananciyar damuwa ta kama, tana fitar da kuzarin da aka adana, yana haifar da sashi tsakanin wurin hutu da wurin sarrafawa don dawowa cikin sauri. Mutanen da ke cikin yankin koma baya suna cikin haɗarin rauni mai tsanani ko ma kisa. Saboda haka, ya zama wajibi masu aikin kebul su nisanta kansu daga wannan wuri mai haɗari, musamman lokacin da kebul ɗin ke cikin tashin hankali, saboda igiyoyin fiber na roba na iya karyewa ba zato ba tsammani ba tare da faɗakarwa ba.

Dokokin Tsaro don Motsawa:Ayyukan kebul a kan ganga bai kamata a gudanar da shi ta mutum ɗaya ba. Mutum na biyu ya wajaba don cirewa ko samar da kasala a cikin kebul don taimakawa ma'aikacin sarrafa ganga. Lokacin sarrafa igiyoyin waya ko nailan, yana da mahimmanci don kiyaye nisa mai aminci daga ganguna, saboda kebul ɗin na iya “tsalle” kuma ya haifar da haɗarin rauni a hannunka. Koyaushe kiyaye amintaccen nesa daga kebul.

Lokacin aikawa: Maris 24-2025