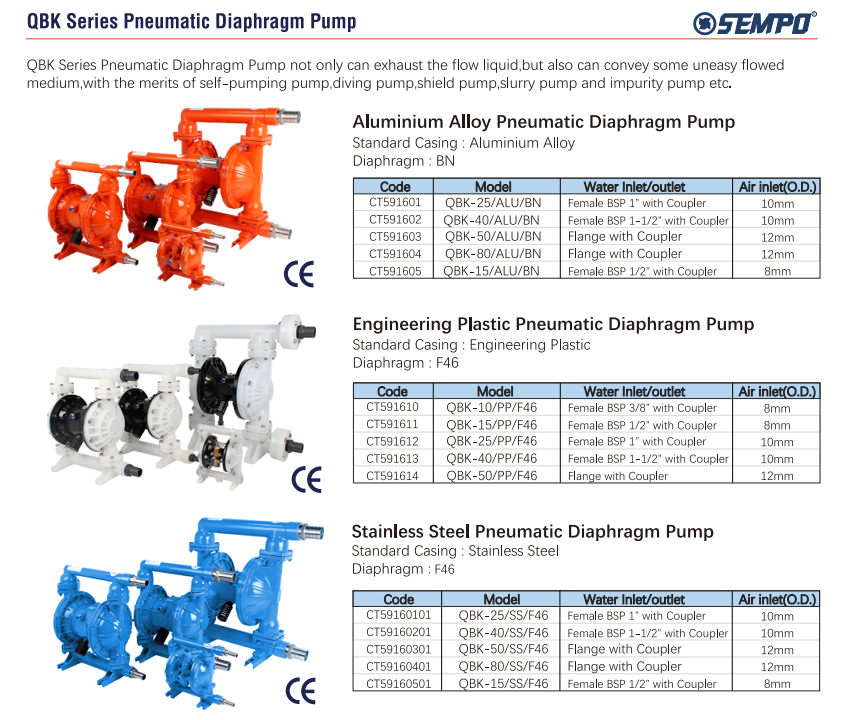

For fluid handling in industrial applications, the QBK series pneumatic diaphragm pump is the best choice. It is versatile and reliable. A critical decision you face is choosing the right pump material. It can greatly affect its performance, lifespan, and application fit. The most common materials for these pumps are: Aluminium Alloy, Engineering Plastic, and Stainless Steel. This article will explore the traits, benefits, and drawbacks of these materials. It will help you make an informed choice.

Understanding the Basics of Pneumatic Diaphragm Pumps

Before diving into the material choices, we must understand the basics of a pneumatic diaphragm pump. Pneumatic diaphragm pumps are positive displacement pumps driven by compressed air. These pumps create a pulsating action. A diaphragm moves back and forth. It alternately draws in and displaces the fluid. These pumps are prized for their ability to handle various fluids and viscosities. So, they suit uses from chemical processing to wastewater treatment.

If you want to learn the working principle of pneumatic diaphragm pump, you can click on this article: What is the marine QBK series pneumatic diaphragm pump? How does it

Material Options for QBK Series Pneumatic Diaphragm Pump

1. Aluminium Alloy

Characteristics:

Aluminium alloy is often used in QBK series pneumatic diaphragm pumps. It’s lightweight and has good mechanical properties. Aluminium alloys resist corrosion and are usually cheaper than other materials.

Advantages:

- Lightweight: Easier to handle and install.

- Moderate Corrosion Resistance: Suitable for non-corrosive and mildly corrosive fluids.

- Cost-Effective: Typically less expensive than stainless steel, making it a budget-friendly option.

Considerations:

- Chemical Compatibility: Not ideal for highly corrosive substances. They may degrade the aluminum over time.

- Strength: It has good mechanical properties. But, it may not be as strong as stainless steel for some demanding uses.

Ideal Applications:

Aluminium alloy suits non-corrosive or mildly corrosive fluids, like water and light chemicals. It’s for budget-sensitive industrial use.

2. Engineering Plastic

Characteristics:

The QBK series pneumatic diaphragm pumps use engineering plastics, like polypropylene and acetal. They are light and have excellent chemical resistance. These plastics also offer good durability and can be molded into complex shapes.

Advantages:

- Excellent Chemical Resistance: Capable of handling a wide range of aggressive chemicals.

- Lightweight: Easier to manage and install compared to metal-based pumps.

- Versatility: Suitable for a variety of applications due to their moldability.

Considerations:

- Temperature Limits: Plastics may not perform well under high temperature conditions.

- Mechanical Strength: They may be less robust than metal pumps. This could be a concern in high-pressure or abrasive applications.

Ideal Applications:

Engineering plastic works well for chemical processing and the food and beverage industries. It is best for applications with aggressive chemicals but not very high temperatures.

3. Stainless Steel

Characteristics:

Stainless steel is known for its outstanding corrosion resistance, strength, and hygienic properties. It is often the best material for high-end industrial uses. These involve extreme conditions and strict sanitary standards.

Advantages:

- Superior Corrosion Resistance: Ideal for both mildly and highly corrosive fluids.

- High Strength: Capable of withstanding high pressure and abrasive materials.

- Sanitary Properties: It is easy to clean. So, it suits food, pharmaceutical, and biotech industries.

Considerations:

- Cost: Stainless steel is generally more expensive than aluminium and engineering plastics.

- Weight: It’s heavier than other materials. This may require more effort to install and maintain.

Ideal Applications:

Stainless steel is best for high-durability uses. These include chemical processing, pharmaceuticals, food and beverage, oil and gas, and marine. It is also advisable when handling highly acidic or alkaline substances.

Making the Choice

To choose the right material for your QBK series pneumatic diaphragm pump, consider these factors:

- Chemical Compatibility: Ensure the material can handle the chemical properties of your fluid without degrading.

- Operating Conditions: Assess the temperature, pressure, and environmental factors of your application.

- Budget Constraints: Balance the initial investment against the expected performance and longevity.

- Maintenance: Consider ease of maintenance and cleaning, given the environment.

By comparing these factors with Aluminium Alloy, Engineering Plastic, and Stainless Steel, you can choose the best material for your needs. This will ensure the efficient operation of your QBK series pneumatic diaphragm pump.

In conclusion, each material has its own set of advantages and limitations. Aluminium alloy is cheap and moderately corrosion-resistant. Engineering plastic is lighter and has excellent chemical resistance. Stainless steel is durable and clean, even in harsh conditions. Knowing these options lets you customize your equipment. This will meet your industrial processes’ specific demands, ensuring reliability and performance.

Post time: Jan-21-2025