In the maritime industry, maintaining the cleanliness of cargo tanks is not just a regulatory requirement but a crucial factor for operational efficiency and safety. With advancements in technology, marine tank cleaning has evolved significantly. This article explores the essential aspects of marine tank cleaning technology, focusing on the Cargo Tank Washing Machine, including its applications, benefits, and how it enhances the overall operations for ship chandlers and marine service providers.

Understanding Marine Tank Cleaning Technology

Marine tank cleaning technology involves specialized equipment designed to clean the interior surfaces of cargo tanks on vessels. One of the most effective tools in this field is the Portable Oil Tank Cleaning Machine. These machines are engineered to remove residues, sludge, and contaminants that accumulate during cargo transportation, ensuring that tanks are ready for the next load without contamination.

What is a Cargo Tank Washing Machine?

A Cargo Tank Washing Machine is specifically designed for cleaning tanks of oil tankers and chemical tankers. These machines come in various models, including fixed and portable types, making them versatile for different cleaning needs. The YQJ series is particularly noteworthy, crafted from high-quality materials like stainless steel and copper alloy, which provide excellent resistance to rust and corrosion.

Key Features of Tank Washing Machines

1. 360° Coverage: The design of tank washing machines allows for 360-degree cleaning coverage, ensuring every inch of the tank is reached.

2. Durability: Made from robust materials, these machines can withstand harsh marine environments.

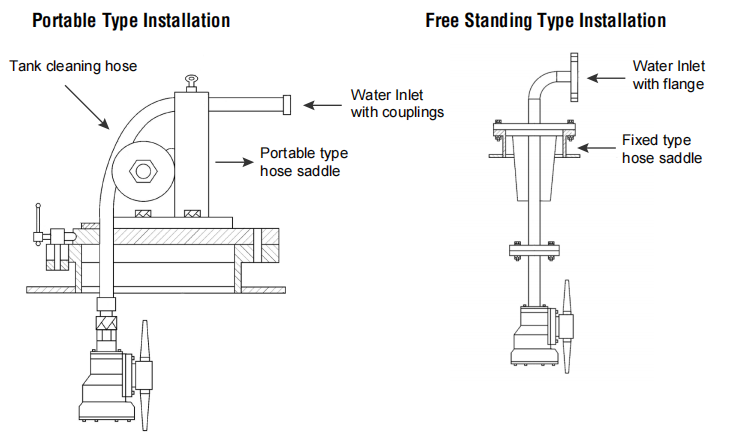

3. Multiple Configurations: Available in both fixed and portable types, they cater to a wide range of operational requirements.

4. Effective Nozzles: Equipped with nozzles ranging from 7 to 14 mm, these machines deliver high-pressure cleaning solutions effectively.

How Do Tank Washing Machines Work?

Understanding the operational mechanics of a Tank Washing Machine is essential for marine service providers and ship chandlers. Here’s a detailed look at how these machines function:

1. Setup and Installation

Before operation, the tank washing machine must be properly installed. Fixed models are secured in a designated location, while portable models can be moved as needed. Each machine is equipped with a strainer to prevent blockages, ensuring uninterrupted cleaning.

2. Supply of Cleaning Medium

The cleaning process begins with a tank cleaning pump supplying the cleaning medium—usually water or a specialized cleaning solution. The YQJ series operates effectively within flow rates of 10 to 40 m³/h and pressure ranges of 0.6 to 1.2 MPa.

3. Cleaning Mechanism

Once the cleaning medium enters the tank washing machine, it drives an impeller and gear mechanism that rotates the nozzles and shell both horizontally and vertically. This 360-degree rotation ensures comprehensive cleaning of all surfaces.

- Cycle Time: The cleaning cycle varies depending on the model. For example, the YQJ-B model completes a cycle in approximately 15 minutes, while the YQJ-Q model takes around 25 minutes under normal pressure conditions.

4. Final Inspection

After the cleaning process is complete, tanks can be inspected to ensure they meet cleanliness standards. This step is crucial for maintaining cargo quality and preventing contamination.

Benefits of Marine Tank Cleaning Technology

The implementation of modern tank cleaning technology offers numerous advantages for ship chandlers and marine service providers:

1. Quality Assurance

Using a Cargo Tank Washing Machine significantly improves the quality of cargoes transported. Any residues left in tanks can lead to contamination, affecting the subsequent loads. Regular cleaning mitigates these risks, ensuring high standards are maintained.

2. Operational Efficiency

Manual cleaning methods are time-consuming and labor-intensive. The automation provided by tank washing machines streamlines the cleaning process, allowing vessels to resume operations more quickly, thus enhancing overall efficiency.

3. Safety Compliance

With stringent regulations governing maritime operations, maintaining clean tanks is often a legal requirement. Employing a Portable Oil Tank Cleaning Machine helps ensure compliance, reducing the risk of penalties and legal issues.

4. Cost-Effectiveness

Investing in a cargo tank washing machine can lead to significant long-term savings. Preventing tank damage and contamination helps avoid costly fines and product losses, making these machines a wise investment for marine supply operations.

The Role of Ship Chandlers in Marine Tank Cleaning

Ship chandlers play a vital role in the marine supply chain, providing essential services and equipment for vessels. Their responsibilities include supplying marine cleaning equipment, such as tank washing machines, and ensuring that ships have access to the tools necessary for maintaining operational efficiency.

By partnering with reliable manufacturers like Chutuo, ship chandlers can offer high-quality tank cleaning solutions that meet the needs of their clients. This collaboration ensures that vessels are equipped with the best technology for maintaining cleanliness and safety standards.

Future Trends in Marine Tank Cleaning Technology

As the maritime industry continues to evolve, so does the technology used in tank cleaning. Future advancements may include:

1. Eco-Friendly Cleaning Solutions: Development of environmentally friendly cleaning agents that minimize ecological impact.

2. Smart Technology Integration: Incorporating IoT technology for real-time monitoring and management of cleaning processes.

3. Automated Systems: Advancements in automation that could further reduce the need for manual intervention during cleaning.

Conclusion

In conclusion, marine tank cleaning technology is an essential aspect of the shipping industry, ensuring that cargo tanks remain clean and compliant with safety regulations. The Cargo Tank Washing Machine, particularly the YQJ series, exemplifies the advancements in this field, providing efficiency, reliability, and thorough cleaning capabilities. For ship chandlers and marine service providers, understanding and utilizing this technology is key to maintaining high operational standards and ensuring the quality of transported goods.

By investing in modern tank cleaning solutions, marine suppliers can enhance their service offerings, contributing to safer and more efficient maritime operations. As technology continues to advance, the future of marine tank cleaning looks promising, paving the way for even greater improvements in safety and efficiency.

Post time: Feb-17-2025