In the maritime industry, maintaining clean cargo holds is critical to operational efficiency and safety. One of the most effective tools for this task is a tank cleaning machine. Among the various factors that influence the efficiency of these machines, nozzle size plays a key role in cleaning performance. This article explores the importance of nozzle size in tank cleaning, particularly in portable tank cleaning machines, and discusses its impact on ship suppliers and marine service operations.

Learn about tank washing machine

The cargo hold cleaning machine is designed to effectively clean the inner surfaces of a ship’s cargo holds. These machines come equipped with various features that enhance their cleaning capabilities. The nozzle is one of the most critical components as it directly affects how the cleaning media is delivered into the tank.

The Importance of Nozzle Size

Nozzle size refers to the diameter of the opening through which the cleaning medium (usually water or a specialized cleaning fluid) flows. The size of the nozzle will significantly affect several key performance indicators of the tank cleaning:

Flow rate: The larger the nozzle, the greater the flow rate of the cleaning medium, which can increase the speed and efficiency of the cleaning process. Conversely, a smaller nozzle will result in a lower flow rate, thus extending the cleaning cycle.

Pressure: Nozzle size affects the pressure at which the cleaning media is delivered. The smaller the nozzle, the greater the spray pressure, effectively removing stubborn residues and contaminants.

Coverage: The size and design of the nozzle determines the pattern of water spray. A well-designed nozzle will provide full coverage, reaching every part of the tank interior, while an ill-fitting nozzle may leave uncleaned spots.

Effective cleaning: Different types of tanks and residues require different cleaning strategies. The nozzle size must be adjusted to match the specific cleaning requirements of the relevant tank.

How nozzle size affects cleaning performance

1. Impact on traffic

In portable tank cleaning machines, nozzle size is directly related to the flow rate of the cleaning media. For example, nozzles in the 7 to 14 mm range are commonly used in tank cleaning applications. Larger nozzles facilitate higher flow rates, allowing the cleaning medium to circulate more freely within the tank. This is especially beneficial when handling large tanks or heavy residues.

2. Impact on stress

The cleaning pressure generated by the machine is essential to effectively clean the tank. Smaller nozzles increase the velocity of the water, creating a high-pressure jet. This is particularly useful for breaking down tough deposits or sludge inside the tank. For example, if the tank contains hardened residue, a smaller nozzle may be more effective in providing the necessary pressure to clean and remove these contaminants.

3. Coverage and efficiency

The design and size of the nozzle will also affect the spray pattern and therefore the coverage area. Well-designed nozzles create a 360-degree spray pattern, ensuring that all surfaces within the tank are effectively cleaned. This full coverage minimizes the need for multiple washes and reduces overall cleaning time.

4. Nozzle size matches cleaning requirements

Different cleaning scenarios require different approaches. For example, cleaning an oil tank may require a different nozzle size than cleaning a chemical tank. The ability to adjust the nozzle size allows operators to tailor the cleaning process to the specific requirements of each tank, improving overall efficiency.

5. Performance data

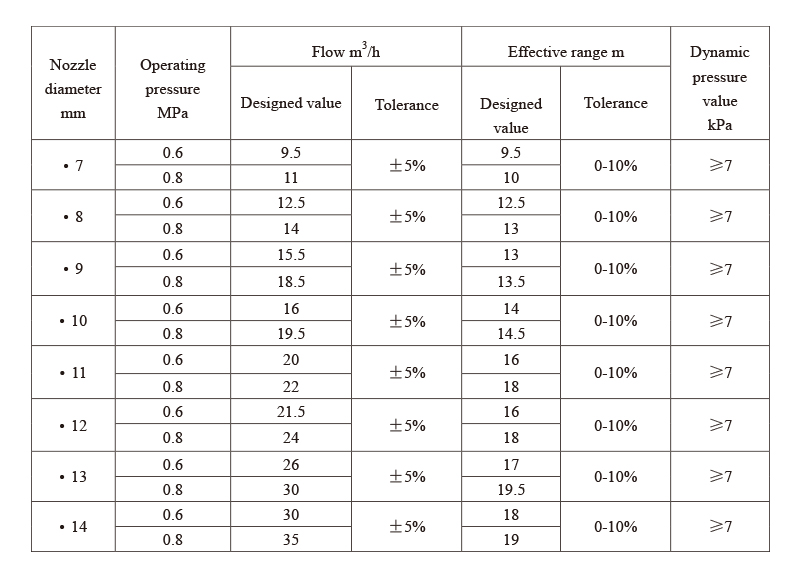

Following table shows the inlet pressure, nozzle diameter, probable flow and jet length for each tank washing machine.

Practical applications in marine operations

It is vital for ship suppliers and marine service providers to understand the role of nozzle size in tank cleaning performance. Here’s how this knowledge translates into real benefits:

1. Improve efficiency

By selecting the right nozzle size for a specific cleaning task, vessel operators can significantly improve efficiency. This can reduce the turnaround time of the vessel, allowing it to return to operations as quickly as possible.

2. Cost savings

Efficient cleaning reduces the amount of cleaning media used, saving costs. Additionally, effective cleaning minimizes the risk of future cargo contamination, protecting the quality of the shipped product.

3. Improve compliance

Maritime regulations often set strict standards for cargo hold cleanliness. Using the proper nozzle size helps operators consistently meet these standards, reducing the risk of penalties or legal issues.

4. Customization to meet diverse needs

Marine service providers often deal with a variety of tank types and cleaning requirements. The ability to adjust the nozzle size allows for greater flexibility and customisation, ensuring every cleaning task is completed to the highest standard.

in conclusion

In conclusion, nozzle size plays a vital role in the performance of the tank cleaning machine. Its impact on flow rate, pressure, coverage area and overall cleaning efficiency cannot be underestimated. For ship suppliers and marine service providers, understanding and optimizing nozzle size is critical to providing effective cleaning solutions that meet industry standards.

As the maritime industry continues to develop, the technology surrounding tank cleaning will also continue to advance. By understanding the importance of nozzle sizing, vessel operators can ensure they make the best choice for their cleaning process, ultimately improving the safety, efficiency and profitability of their operations. Investing in a high-quality portable tank cleaning machine with adjustable nozzle size will not only improve cleaning results but also contribute to the long-term success of your vessel operations.

Post time: Feb-19-2025