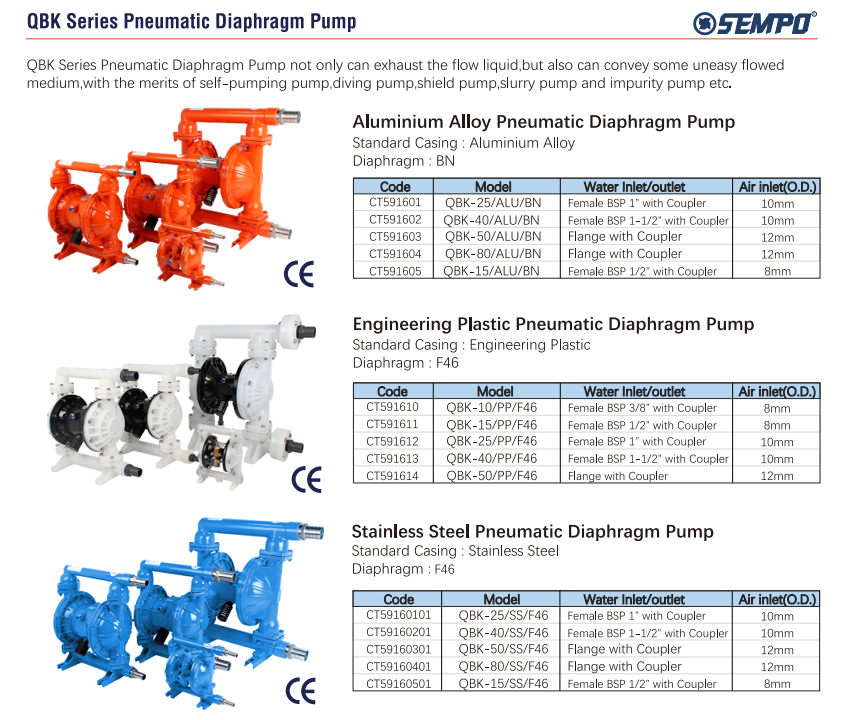

The QBK series has high-performance, CE-certified aluminum diaphragm pumps. They are durable and efficient in demanding applications. Pneumatic diaphragm pumps, like the QBK series, are widely used in industries from chemical processing to water treatment. They can handle a vast range of fluids. However, to keep these pumps working well, it’s vital to use them correctly.

Understanding the QBK Series Aluminum Diaphragm Pump

Before diving into the procedures, you must grasp the QBK series pneumatic diaphragm pumps’ key features:

1. Material Composition:

The QBK series is made of aluminum. It is lightweight but strong. This makes it ideal for industrial use. The aluminum casing is durable and corrosion-resistant. It’s safe for aggressive chemicals and abrasive materials.

2. Certification:

QBK series pumps are CE certified. They meet the European market’s safety, health, and environmental standards. This certification underpins the quality and reliability of the pumps.

3. Pump Mechanism:

As pneumatic diaphragm pumps, the QBK series operates using compressed air. The diaphragms’ movement, driven by air pressure, creates a flow path for the pumped fluid. This ensures efficient and consistent transfer rates.

Steps to Operate the QBK Pneumatic Diaphragm Pump Correctly

To operate the QBK series pneumatic diaphragm pump, you must know its setup, maintenance, and operating protocols. Here are the detailed steps:

Step 1: Installation

- Positioning:

Install the pump in a well-ventilated, accessible location. Ensure it is securely mounted to prevent vibrations and movements during operation. Prevent sparks from static electricity due to vibration, impact, and friction during operation. This will avoid serious accidents. It is best to use an antistatic hose for the air intake.)

- Air Supply Connection:

Connect the air supply line to the pump’s air inlet. The air supply must be clean, dry, and at the right pressure. The intake pressure cannot exceed the diaphragm pump’s max allowable operating pressure. Excessive compressed air will rupture the diaphragm and damage the pump. In the worst case, it may cause production stoppage and personal injury.)

- Fluid Inlet and Outlet:

Connect the fluid inlet and outlet hoses using suitable fittings. Ensure that all connections are secure and leak-free. The hoses should be compatible with the fluid being pumped.

Step 2: Pre-Operation Checks

- Inspect the Diaphragms:

Before starting the pump, check the diaphragms for any signs of wear or damage. Replace the diaphragms if necessary to avoid any operational failures.

- Check for Obstructions:

Ensure that the fluid path (both inlet and outlet) is free of obstructions. Any blockage can hinder the pump’s efficiency and cause damage.

- Check Air Supply Quality:

Ensure the air is free of contaminants, like oil, water, and dust. An air filter regulator can ensure a clean, consistent air supply. (When the diaphragm pump runs, its compressed air source will have solid particles. So, never point the exhaust port at the work area or people to avoid injury.)

Step 3: Starting the Pump

- Gradual Air Pressure Increase:

Start the pump by slowly increasing the air pressure. This prevents a sudden surge that could damage the diaphragms or other internal parts.

- Monitor Initial Operation:

Watch the pump’s start-up. Look for any strange noises or vibrations. Ensure that fluid is flowing smoothly through the inlet and outlet hoses.

- Adjust Flow Rate:

Adjust the air pressure to achieve the desired flow rate. The QBK series pumps allow precise flow control by varying the air pressure. This makes them versatile for different uses.

Step 4: Routine Operation and Maintenance

- Regular Monitoring:

While the pump runs, check the air pressure, fluid flow, and performance. Address any irregularities immediately to prevent long-term damage.

- Scheduled Maintenance:

Create a maintenance schedule. It must include regular inspections of diaphragms, valves, seals, and the air supply system. Replace worn-out parts as per the manufacturer’s guidelines to maintain optimal performance.

- Clean the Pump:

Periodically clean the pump, especially if the fluids leave residues. This practice helps in preventing clogs and maintaining the pump’s efficiency.

- Lubrication:

Some models may require periodic lubrication of moving parts. Refer to the manufacturer’s manual for lubrication intervals. Use only approved lubricants.

Step 5: Safe Shutdown

- Gradual Pressure Reduction:

When shutting down the pump, reduce the air pressure slowly. This avoids sudden halts that might create back pressure on the diaphragms.

- Depressurize the System:

Fully depressurize the system before disconnecting the air supply or doing any maintenance. This step ensures safety and prevents injuries due to pressurized components.

-Fluid Drainage:

If the pump will be idle for a long time, drain any remaining fluid. This will prevent damage from residual chemicals or build-up.

Conclusion

The QBK series aluminum pneumatic diaphragm pumps are strong and efficient. They are for industrial fluid handling. But, like all complex machines, they need proper use and care to work their best. By following the steps above, you can ensure your QBK pneumatic diaphragm pump works correctly. This will maximize its lifespan and keep it reliable in all applications.

Post time: Jan-15-2025