Ships are highly dependent on the functionality of their equipment to ensure smooth operation. Among them, QBK series air-operated diaphragm pumps are an integral part of maintaining the fluid management system on board. Although these pumps are designed for harsh marine environments, they are not immune to operational problems. This article will discuss common issues associated with marine QBK series air-operated diaphragm pumps and provide actionable troubleshooting tips, emphasizing compliance with CE (European Standards) safety standards.

Learn about QBK Series Air Operated Diaphragm Pumps

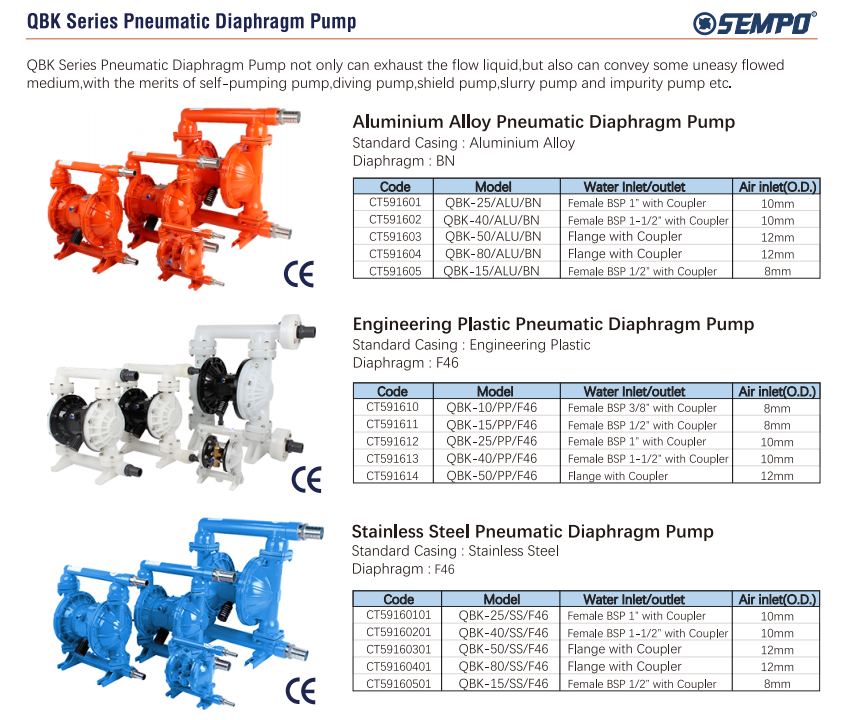

Before diving into troubleshooting, it is important to understand the basic working principles of the QBK Series Air Operated Diaphragm Pumps. These pumps are driven by compressed air, which powers the oscillation of two diaphragms. This oscillation creates a vacuum that draws fluid into the pump chamber and subsequently pushes it out the other end. With no electrical components and reliance on air pressure, these pumps are suited to handling abrasive, viscous, and corrosive fluids commonly found in marine environments.

To learn more about the principle of pneumatic diaphragm pump, please click this article: What is the marine QBK series pneumatic diaphragm pump? How does it work?

Common Problems and Troubleshooting Methods

1. Insufficient liquid flow

Symptoms:

Decreased or irregular fluid output.

Possible causes:

- Air supply problem

- Diaphragm is worn or damaged

- Hose is clogged or leaking

- Improper installation

Troubleshooting Steps:

- Check the Air Supply: Confirm that the compressed air supply is steady and within the recommended pressure range for the pump (usually 20-120 PSI). Check for any leaks in the air hose or connections

- Inspect the Diaphragm: Remove the pump cover and inspect the diaphragm. If the diaphragm shows signs of wear, tear or pinholes, it should be replaced immediately.

- Clean hoses: Make sure all water inlet and outlet lines are free of obstructions or blockages. Also, check for any leaks that could cause a drop in pressure.

- Verify Installation: Confirm that the pump has been properly installed per the manufacturer’s instructions. Improper installation may result in air leaks and reduced efficiency.

2. Air valve failure

Symptoms:

Pump operates erratically or does not operate consistently.

Possible causes:

- Contamination in the air valve

- Worn or damaged valve components

- Improper lubrication

Troubleshooting Steps:

- Cleaning the Air Valve: Disassemble the air valve assembly and thoroughly clean all parts. Accumulated dirt or debris will impede the function of the valve.

- Inspect Valve Assembly: Check for any worn or damaged parts such as gaskets, o-rings or seals. Replace any defective parts as necessary.

- Proper Lubrication: Make sure the air valve is properly lubricated with the proper oil specified by the manufacturer. Over-lubrication or use of an unsuitable lubricant can cause sticking and binding.

3. Leakage

Symptoms:

Visible fluid leakage from pump or hose connection.

Possible causes:

- Loose fittings or connections

- Diaphragm failure

- Pump casing cracked

Troubleshooting Steps:

- Tighten the connections: First check and tighten all hose connections to ensure they are secure.

- Replace Diaphragm: If the diaphragm is damaged or cracked, replace it following the exact procedures outlined in your pump maintenance manual.

- Inspect Pump Casing: Inspect the pump casing for cracks or damage. Cracks may require repair or complete replacement of the pump casing to prevent environmental contamination and maintain efficiency.

4. Excessive noise

Symptom:

Unusual or excessive noise during operation.

Possible causes:

- Inconsistent air supply

- Wear of internal components

- Loose internal parts

Troubleshooting Steps:

- AIR SUPPLY CHECK: Make sure the air supply is steady and within the recommended pressure range. Inconsistent air pressure will cause the pump to work harder and make more noise.

- Inspect Internally: Open the pump and inspect internal components for wear or damage. Replace any worn parts such as diaphragms, valve balls or seats.

- Secure Internal Parts: Verify that all internal components are securely fastened. Loose parts may cause rattling and increase noise levels.

Maintain CE compliance

For marine QBK Series Air Operated Diaphragm Pumps, adherence to CE standards is critical for safety and environmental compliance. Ensure that any repairs or replacements use CE certified components. Proper documentation of maintenance and troubleshooting work is essential to demonstrate ongoing compliance with regulatory requirements. Regular calibration and certification checks also help maintain compliance with CE guidelines.

In conclusion

The marine QBK series air-operated diaphragm pumps are essential components in a vessel’s fluid management system. Regular maintenance and timely troubleshooting can ensure long service life and reliable performance. Following the above steps will help to effectively solve common problems and ensure smooth operation in harsh marine conditions while maintaining compliance with key CE safety standards. Remember that thorough inspections, timely repair of damaged parts, and adherence to correct installation and maintenance procedures are key to the efficient operation of these important pumps.

Post time: Feb-06-2025