In the maritime sector, the utilization of specialized equipment is vital for maintaining safety and efficiency across various operations. One such essential tool is the Marine Pneumatic Driven Winch. These winches play a critical role in activities ranging from lifting substantial weights to cleaning tanks. For those involved in ship supply or as ship chandlers, a comprehensive understanding of pneumatic driven winches can prove advantageous. In this context, we address ten commonly asked questions regarding marine pneumatic driven winches to enhance your knowledge of their operation, benefits, and uses.

1. What is a Marine Pneumatic Driven Winch?

A Marine Pneumatic Driven Winch is a winch that functions using compressed air as its energy source. Unlike electric or hydraulic winches, which depend on electricity or hydraulic fluids, pneumatic winches are specifically designed for settings where electrical equipment may present safety hazards. They are frequently employed for lifting, pulling, and securing loads in marine environments.

2. How do Pneumatic Driven Winches operate?

Pneumatic driven winches operate by utilizing the energy from compressed air. The process initiates when compressed air is delivered from an air compressor to the winch. This air enters through an inlet and powers a pneumatic motor within the winch. The motor transforms the air pressure into mechanical energy, which in turn rotates the winch drum. As the drum rotates, it either winds or unwinds the connected wire rope, facilitating the lifting or pulling of heavy loads.

Click the link to watch the Pneumatic Driven Winches test video: Pneumatic Driven Winches: product test display

3. What are the primary characteristics of Marine Pneumatic Driven Winches?

Marine pneumatic driven winches are equipped with several essential characteristics:

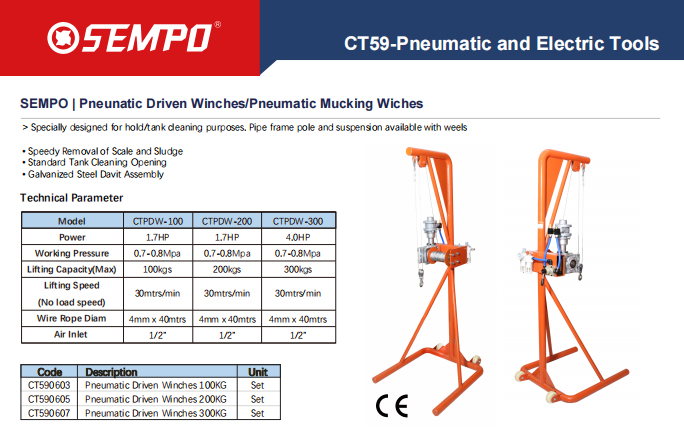

Lifting Capacity: Models such as the CTPDW-100, CTPDW-200, and CTPDW-300 have lifting capabilities ranging from 100 kg to 300 kg, making them appropriate for various applications.

Operating Pressure: These winches generally function at an operating pressure of 0.7 to 0.8 Mpa, ensuring dependable performance.

Lifting Speed: With a no-load lifting speed reaching up to 30 meters per minute, pneumatic winches can accomplish tasks efficiently.

Robustness: Constructed from galvanized steel, these winches are designed to endure challenging marine conditions.

Safety Mechanisms: They are equipped with both dynamic and mechanical braking systems to guarantee safe operation during lifting activities.

4. What are the appropriate applications for Marine Pneumatic Driven Winches?

Marine pneumatic driven winches are adaptable and can be utilized in a variety of applications, including:

Tank Cleaning: They are specifically engineered for tank cleaning tasks, effectively eliminating sludge and scale.

Mooring: Pneumatic winches facilitate the secure mooring of vessels by managing the lines used for docking.

Cargo Handling: They are well-suited for lifting and transporting heavy cargo, making them vital for efficient loading and unloading processes.

Maintenance Activities: These winches aid in lifting tools and equipment during maintenance and repair operations on ships.

5. What are the benefits of utilizing Pneumatic Driven Winches?

Marine pneumatic driven winches offer numerous benefits, including:

Safety: The reliance on compressed air minimizes the potential for electrical hazards, enhancing safety during operations in wet conditions.

Efficiency: With high lifting speeds and capacities, these winches significantly improve operational efficiency, facilitating faster task completion.

Durability: Engineered to endure challenging marine environments, these winches require less frequent maintenance compared to other types.

Versatility: Their capability to perform various functions makes them an invaluable resource for ship chandlers and marine service providers.

Ease of Use: Pneumatic winches are designed for user-friendliness, featuring simple controls that allow for effortless operation.

6. How should I maintain a Marine Pneumatic Driven Winch?

To ensure the longevity and optimal performance of pneumatic driven winches, proper maintenance is crucial. Consider the following maintenance recommendations:

Regular Inspections: Examine the winch for any indications of wear or damage, especially on the air hoses and fittings.

Air Supply Checks: Verify that the compressed air supply is stable and at the appropriate pressure to prevent operational complications.

Lubrication: Consistently lubricate moving components to minimize friction and wear.

Cleanliness: Maintain the winch free from debris, salt, and other contaminants that could impair its performance.

This article describes in detail how to maintain a Pneumatic Driven Winches: How to Maintain Your Marine Pneumatic Driven Winch for Optimal Performance

7. Are there particular installation requirements for these winches?

Indeed, the installation of marine pneumatic-driven winches necessitates specific considerations:

Air Supply: It is essential to have a dependable source of compressed air that meets the required pressure specifications.

Mounting: The winch should be securely mounted on a stable surface to avoid any movement during operation.

Safety Equipment: It is important to install necessary safety features, such as emergency stop buttons and safety guards, to ensure operator protection.

8. What factors should I take into account when buying a Pneumatic Driven Winch?

When acquiring a pneumatic driven winch, consider the following aspects:

Lift Capacity: Select a model that aligns with your lifting needs, such as the CTPDW-100, CTPDW-200, or CTPDW-300.

Operating Pressure: Verify that the winch operates at a pressure that is compatible with your air supply system.

Durability: Opt for winches constructed from corrosion-resistant materials that are appropriate for marine conditions.

Manufacturer Reputation: It is advisable to purchase from well-regarded manufacturers like Chutuo, recognized for their high-quality marine equipment.

9. In what ways do Marine Pneumatic Driven Winches differ from electric winches?

Marine pneumatic driven winches present several notable benefits compared to electric winches:

Safety: Pneumatic winches are safer to use in wet or potentially explosive environments, as they eliminate the hazards associated with electricity.

Power Source: Electric winches depend on a consistent power supply, which may not always be accessible in marine environments.

Heat Management: Pneumatic winches are less prone to overheating than their electric counterparts, making them ideal for prolonged use.

Nonetheless, electric winches may offer simpler operation in areas where a reliable power source is available.

10. Where can Marine Pneumatic Driven Winches be purchased?

High-quality marine pneumatic driven winches can be sourced from supplier such as Chutuo, which specializes in marine equipment. Their product line features various models tailored to meet diverse lifting requirements. For inquiries or to place an order, you may reach out to them directly via email at marketing@chutuomarine.com.

Conclusion

A comprehensive understanding of Marine Pneumatic Driven Winches is crucial for individuals engaged in maritime operations, particularly ship chandlers and marine service providers. By addressing these frequently asked questions, we aim to clarify the functionality, benefits, and applications of pneumatic driven winches. Whether your goal is to enhance safety, efficiency, or versatility in your operations, investing in a pneumatic driven winch can significantly enrich your marine equipment collection.

Post time: Mar-19-2025