Brake Testing

In compliance with OCIMF standards, it is essential to conduct a brake force test on the Mooring winch prior to delivery, annually, and following any repairs or significant events that could affect the brake force. Based on the outcomes of these tests, the brake will be fine-tuned to achieve a braking capacity of 60% to 80% of the minimum breaking load (MBL) of the mooring cable. This adjustment ensures that if the external force exceeds the designated brake force, the Mooring winch will automatically release, thereby preventing any potential breakage or damage to the Mooring winch.

Braking force test principle video:

Braking Force Testing and Adjustment

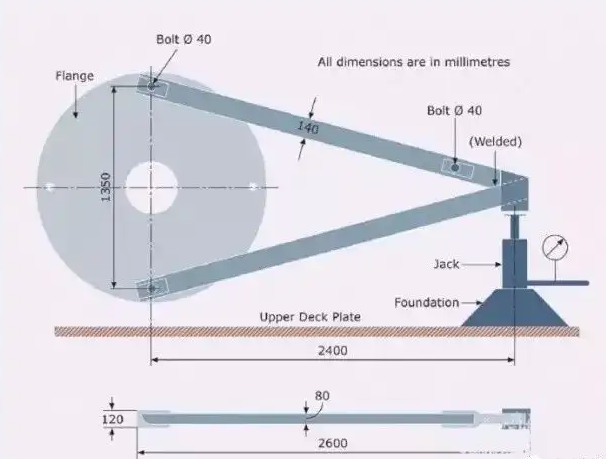

Begin by reviewing the cable certification and other relevant information, along with field measurements, to gather the necessary snow data for calculations. The jack and mooring winch, equipped with a pressure gauge, must include an opening for securing the dry jack or utilizing clamping bolts.

The calculation formula is as follows: T = FxLI/L2 (Kn).

In this formula, T represents the calculated jack force (in Kn), which should be determined based on the minimum breaking force of the ship’s cable. This calculation will yield the jack force reading that corresponds to the required braking force, which is either 60% or 80% of the cable’s breaking force. F denotes the braking force of the mooring winch (in Kn). Ll is the distance from the center of the mooring winch roller to the center of the cable, calculated as the sum of the inner roller radius and the cable radius. L2 indicates the horizontal distance from the center of the jack bracket to the central axis.

Test Procedure:

1. Operate the mooring winch to eliminate any moisture, grease, or other substances that may impair the performance of the brake pads.

2. Properly connect the testing device to the mooring winch, ensure the brakes are tightened to standard levels, and disengage the winch’s clutch.

3. Use the jack to apply pressure, and monitor the pressure gauge reading at the moment the brake begins to slip, recording the value observed.

4. If the reading falls below the predetermined value, this indicates inadequate brake force, necessitating either tightening or repair of the brake, followed by a retest.

5. If the reading aligns with the calculated value, it confirms that the brake force meets the established criteria.

6. If the mooring winch does not slip while the jack reading exceeds the calculated value, this suggests that the brake is overly tight, resulting in excessive brake force. In this case, the brake force should be reduced by adjusting the brake screw, followed by a retest.

Most vessels perform their own brake force adjustments, typically by modifying the limit screw on the brake handle to regulate the brake’s tightness for optimal force.

For brake handles lacking limit screws, one can identify a position after the brake is tightened (corresponding to the desired braking force) and mark both the brake handle and brake band at that point (creating a limit mark on the brake screw). In future operations, aligning the upper and lower marks will indicate that the braking force at this level corresponds to the set braking force.

After completing the brake test, the date of the test and the measured braking force should be prominently displayed on the mooring winch and meticulously documented in the mooring equipment maintenance log.

Mooring Safety Measures

In addition to regularly testing and adjusting the brake force, attention must also be given to the following aspects during mooring operations:

Mooring Elasticity: The elasticity of the mooring cables plays a crucial role in distributing the total force exerted by the ship among the mooring lines. For instance, if two mooring cables of identical size and material are secured to the dock in the same direction but differ in length—one being twice as long as the other—the shorter cable will endure two-thirds of the load, while the longer cable will only take on one-third. Therefore, it is advisable to use mooring cables of equal length whenever possible.

In cases where two mooring cables are of the same length, possess the same breaking strength, and are aligned in the same direction but are made from different materials—such as a steel wire cable with an elongation of 1.5% and a synthetic fiber cable with an elongation of 30%—the load distribution will be significantly unequal. The steel wire cable will carry 95% of the load, while the fiber rope will only support 5%. Hence, it is essential to utilize cables of the same material for mooring lines in the same direction.

It is important to recognize that ensuring the safety of a ship during mooring (secure mooring) involves not only coordination and consistency but also a comprehensive understanding of the ship’s mooring equipment, a solid grasp of mooring principles, and meticulous planning and execution. The process of maintaining the ship’s position at the berth begins only after the vessel is secured, marking the start of ongoing seamanship practices.

Mooring Winch Braking Force: The braking force of a mooring winch varies for each vessel and is engineered based on the “cable loosening” force exerted on the cable. This force is influenced by the number of cable layers and the winding direction. The quantity of cable layers on the drum significantly impacts the braking force of the mooring system. For mooring machines that lack separation drums, the braking force is typically calibrated for a specific number of layers. Therefore, it is crucial to ensure that the cables are wound neatly on the drum without accumulating on one side, as this can diminish the braking force. In the case of cable winches equipped with separation drums, it is essential to maintain no more than one layer of cable on the force drum to prevent a reduction in braking force.

The correct winding of the cable is vital, as improper winding can lead to a reduction in braking force by up to 50%.

Improper Brake Usage: Crew members often mistakenly use the brakes to loosen the cable when it is under tension, which is an incorrect approach. This practice can lead to uneven wear on the brake belt and poses safety risks due to its uncontrollable nature. If a balanced load is suddenly applied to the unloosened cable, it may snap, resulting in potential accidents. The appropriate method involves engaging the clutch and using power to gently loosen the cable.

Nylon Cable Pile-Pulling Technique: When securing the nylon cable to the pile, avoid relying solely on the “∞” knot for tightening. Instead, make two turns (with some recommending a single turn, but not exceeding two) to first pull the cable on the ship’s side, followed by forming an “∞” knot (for larger mooring piles) or wrapping around two piles once before creating the “∞” knot (for smaller mooring piles). This technique allows for better control of the cable and enhances safety.

Hazardous Zone During Cable Breakage: The most perilous aspect of synthetic fiber cables occurs when a cable breaks and rebounds unexpectedly. When a stressed cable snaps, it releases stored energy, causing the segment between the break point and the control point to rebound rapidly. Individuals present in the rebound zone are at risk of severe injury or even fatality. Consequently, it is imperative for cable operators to steer clear of this hazardous area, particularly when the cable is under significant tension, as synthetic fiber cables can break suddenly and without warning.

Safety Guidelines for Mooring: The operation of the cable on the drum head should not be conducted by a single individual. A second person is necessary to either remove or provide slack in the cable to assist the operator managing the drum. When handling wire or nylon cables, it is crucial to maintain a safe distance from the drum, as the cable may “jump” and pose a risk of injury to your arms. Always keep a safe distance from the cable.

Post time: Mar-24-2025