Pilot ladders play a vital role in maritime operations, facilitating safe access for pilots as they board and disembark from vessels. Nevertheless, like any equipment, they present certain challenges. Gaining insight into the common issues related to pilot ladders, particularly GOOD BROTHER Pilot Ladders, enables marine professionals to reduce risks and promote safety at sea. This article will examine the typical problems faced with pilot ladders and consider how innovative solutions, such as safety magnet lockers, can improve their functionality.

1. Material Degradation

A primary concern with pilot ladders is the degradation of materials over time. The marine environment is often unforgiving, with exposure to saltwater, sunlight, and wind contributing to the deterioration of the ladder’s components. GOOD BROTHER Pilot Ladders are made from high-quality materials, including manila ropes and steps crafted from beech or rubber wood, which are intended for longevity. However, even the most durable materials can experience wear if not adequately maintained.

Prevention and Upkeep

Conducting regular inspections is essential. Ship chandlers and vessel operators should implement a routine maintenance schedule to examine for frayed ropes, loose steps, or other indicators of wear. Adhering to the care guidelines specified in ISO 799-2-2021 can help extend the lifespan of the pilot ladders. Furthermore, establishing a comprehensive maintenance protocol can significantly reduce the risks associated with material degradation.

2. Instability During Use

The stability of pilot ladders is of utmost importance. An unstable ladder can present significant dangers to pilots, particularly in turbulent seas or unfavorable weather conditions. GOOD BROTHER Pilot Ladders are equipped with features such as rubber steps for enhanced grip and spreader steps to improve stability. Nevertheless, improper installation or external environmental factors may still jeopardize stability.

Innovative Solutions

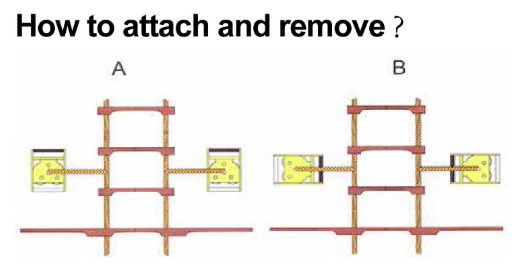

To mitigate stability concerns, the implementation of safety magnet lockers can prove advantageous. These lockers serve as securely removable anchor points for the ladder on the vessel’s side, ensuring that the ladder remains firmly in place and stable during operation. By integrating such devices, marine professionals can greatly improve safety for both pilots and crew members.

3. Compliance with Safety Standards

Adhering to international safety standards is essential for pilot ladders. Regulations such as IMO A.1045(27) and ISO 799-1:2019 outline guidelines that guarantee the safety and dependability of pilot ladders. However, numerous vessels may not routinely verify whether their equipment aligns with these standards, which could result in potential legal and safety complications.

Ensuring Compliance

It is crucial for ship chandlers and operators to remain updated on the latest regulations and confirm that their GOOD BROTHER Pilot Ladders comply with all required standards. Additionally, regular training for crew members on compliance and safety procedures can significantly contribute to upholding high safety standards.

4. Limited Visibility and Identification

A prevalent concern is the visibility of pilot ladders in low-light situations. A ladder that is hard to see can elevate the likelihood of accidents. GOOD BROTHER Pilot Ladders are equipped with fluorescent yellow markers to improve visibility; however, there may still be circumstances where lighting conditions hinder identification.

Improving Visibility

In addition to utilizing ladders with enhanced visibility features, marine operators should consider implementing superior lighting solutions in the boarding area. Ensuring that the area around the pilot ladder is adequately illuminated can significantly decrease the risk of accidents during nighttime operations or adverse weather conditions.

5. Inadequate Handling and Storage

Pilot ladders can be unwieldy to manage and store, which may lead to potential damage if not handled correctly. Improper storage can cause kinks, knots, or other types of damage that undermine the ladder’s structural integrity. GOOD BROTHER Pilot Ladders are designed for ease of handling, but it is crucial for crew members to receive training on appropriate storage methods.

Best Practices for Handling and Storage

Establishing clear protocols for the handling and storage of pilot ladders can help reduce the risk of damage. Employing storage solutions, such as dedicated storage boxes or racks, can ensure that the ladders remain in optimal condition when not in use. Additionally, training crew members on these protocols is vital for preserving the equipment’s durability.

6. Environmental Factors

Environmental conditions, including exposure to saltwater, humidity, and temperature variations, can negatively impact pilot ladders. These elements may result in the corrosion of metal components, deterioration of ropes, and distortion of wooden steps. Although GOOD BROTHER Pilot Ladders are engineered to endure marine environments, prolonged exposure can still have detrimental effects.

Protective Measures

To mitigate the effects of environmental factors, it is essential to adopt protective measures. This involves routinely cleaning the ladders to eliminate salt and debris, as well as applying protective coatings when necessary. Furthermore, utilizing equipment such as the pilot ladder safety magnet locker can help maintain the ladder’s integrity by securing it when not in use.

Conclusion

Pilot ladders are crucial instruments in the maritime sector, facilitating the safe boarding and disembarking of pilots. Nevertheless, prevalent issues such as wear and tear, instability, compliance difficulties, visibility concerns, improper handling, and environmental factors can influence their effectiveness. By recognizing these challenges and implementing practical solutions, including regular maintenance, training, and innovative products like safety magnet lockers, marine professionals can improve the safety and reliability of GOOD BROTHER Pilot Ladders.

Investing in high-quality pilot ladders and ensuring their proper maintenance is vital for ship chandlers and marine supply companies. By addressing these common challenges, the maritime industry can maintain safe and efficient operations on the open seas.

Post time: Feb-28-2025