The marine QBK series pneumatic diaphragm pump is vital for fluid transfer in the marine industry. It has a CE-certified aluminum diaphragm. These pumps can handle many liquids. They include water, slurries, and corrosive chemicals. Understanding the pneumatic diaphragm pump involves exploring both its construction and operation principles.

What is a Marine QBK Series Pneumatic Diaphragm Pump?

The marine QBK series pumps are known for their tough build. They perform reliably in challenging conditions. They are pneumatic diaphragm pumps. It stands out for its versatile abilities and durable, aluminum diaphragm. These pumps are pneumatically operated. They use compressed air as their power source. This makes them ideal for marine environments where electrical power is limited or dangerous.

Key Features of the Pneumatic Diaphragm Pump

1. CE Certification:

The pump meets strict EU standards for safety, efficiency, and eco-friendliness. This certification is vital in the maritime sector. Safety and reliability are paramount there.

2. Aluminum Diaphragm:

It is a key part of the pneumatic diaphragm pump. Aluminum is chosen for its excellent strength-to-weight ratio, corrosion resistance, and heat conductivity. These properties make the pump suitable for harsh marine environments. It is often exposed to saltwater and varying temperatures.

3. Pneumatic Operation:

The pump uses compressed air. This removes the need for electrical parts. So, the pneumatic diaphragm pump is safe in explosive atmospheres. It also cuts maintenance and lowers the risk of electrical failures in a wet, corrosive marine environment.

How Does the Marine Pneumatic Diaphragm Pump Work?

To understand the pneumatic diaphragm pump, we must examine its internal mechanics.

1. Air Chambers:

The key to the pump’s operation lies in its air chambers. These chambers use compressed air to alternate between a vacuum and pressure on either side of the diaphragm.

2. Diaphragm Movement:

Compressed air enters an air chamber. It pushes against the diaphragm, creating a pressure difference. The aluminum diaphragm, for durability, flexes and displaces fluid to the discharge outlet. When the air pressure is relieved, the diaphragm returns to its original position, drawing more fluid into the pump.

3. Valves:

The pump incorporates inlet and outlet valves in each chamber. These valves control the fluid’s direction. They ensure it moves from the inlet to the outlet without backflow. The valves’ timing and coordination are vital for the pump’s efficiency.

4. Fluid Chambers:

The diaphragm’s movement causes suction and discharge in the fluid chambers. This enables the pump to handle various types of liquids. The separation between air and fluid chambers ensures that the pumped fluid does not touch the moving parts.

Working Principle

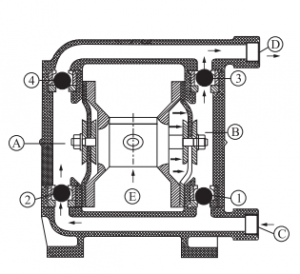

There installs each diaphragm in both aligned working cavities(A)&(B), which can be connected together with a central coupling lever. The compression air enters the air distribution valve from the pump. It draws the air into one cavity. The air distribution mechanism pushes out the diaphragm in that cavity. The gas in another cavity will be drained. When it reaches the stroke terminal, the air system will draw the compressed air into another cavity. It will push out the diaphragm to move in the opposite direction. This will cause both diaphragms to move in sync.

The compression air enters the air distribution valve from (E) in the diagram. It moves the diaphragm piece. The suction force in (A) lets the medium flow in from (C). This pushes out the ball valve (2) to enter (A). The suction force locks the ball valve (4). The medium in (B) is then pressed. This pushes out the ball valve (3) to flow out from the exit (D). Meanwhile, let the ball valve(l)close, to prevent backflow. Such movement in circles will let the medium uninterruptedly suck from(C)entrance and drain from(D)exit.

The marine QBK pneumatic diaphragm pump, with its CE-certified aluminum diaphragm construction, offers a reliable and efficient solution for various liquid transfer needs in the marine industry. Its robust pneumatic operation, combined with versatile application capabilities, makes it an indispensable tool for maintaining the safety and efficiency of marine operations. It is recommended to use Nanjing Chutuo Shipbuilding Equipment Co.,Ltd.’s high-quality pneumatic diaphragm pump. We are currently doing promotions. If you are interested, please contact me as soon as possible.

Post time: Jan-13-2025